In a rural part of Sheffield stands the remains of a once-thriving ceramics factory. After a little research on the web I found out that John Dyson opened his first factory, producing bricks, in Sheffield, in 1834 during the Industrial Revolution and later moved to this site.

The 1834 Sheffield trade directory lists – “John Dyson – Brick Maker, Stannington” which indicates that he ran the business on his own. However, by 1838 the business was listed as “John Dyson and Son – Black clay miners and firebrick manufacturers, Griffs House, Stannington. The son referred to was John his eldest son.

Dyson’s were manufacturers of Refractory material, ceramics for the steel industry, also producing firebacks and other household ceramic bricks for the likes of Aga’s etc. During the 19th century the business thrived due to an increased demand for heat-resistant bricks which the company specialised in. By the late 1950s the company had expanded to include three clay preparation plants. Each was equipped with modern, gas-firing tunnel kilns, as well as ten intermittent kilns.

The factory closed its doors in 2006 and since then the gutted remains have been left to rust. It is soon to be demolished so I decided to visit while I still can and accompanied two fellow urbexers, one of whom was Judderman, who have both visited the site more than once. First the graff . . .

There were a variety of industrial bits and bobs left behind.

The site is quite large and with so much to see, time passed very quickly. The building housing the kilns was almost pitch dark, save for the odd hole letting in a little light. The kilns were long brick tunnels which one could walk through. The heat must have been intense when the kilns were fired up.

Upstairs was a huge space, but with extremely dodgy flooring and asbestos!

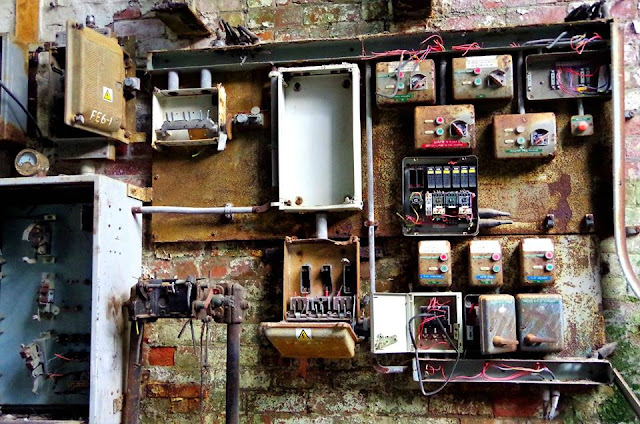

Then onto another part of the site. This was the control room.

Through to yet another part of the site and upstairs we found a treasure trove of a workshop/ store room. It was here that I found a newspaper from 1997.

Blueprints for Northern Petroleum in Iraq.

How rusty can a can of paint get?

Well there had to be a Dyson vacuum cleaner in a place called Dyson's!

There's always the obligatory pair of boots . . .

Dyson's manufacturing process relied heavily on gas fired kilns. With increased energy costs the plant was no longer economically viable and closed around 2006. There are plans in place to build 88 homes on the site but nothing has happened since the planning permission was granted in 2015. I'm glad that I got the chance to explore this place, rich in our industrial heritage. I rather enjoyed it.

Very good write up and cracking pictures m'dear :)

ReplyDeleteThank you kind Sir!

ReplyDelete